Lower Running Cost 100kw Fuel Cells Power Output Analyzer for Reliability Testing

Overview Hydrogen Fuel Cell Test Equipment Lower Running Cost 100Kw Fuel Cells Power Output Analyzer For Reliability Tes

Overview

Lower Running Cost 100Kw Fuel Cells Power Output Analyzer For Reliability Testing

Basic Info.

| Model NO. | WBHTS-100 |

| Solutions | Regenerative Type |

| Gas Flow Control Accuracy | ≤±(0.8%Rd+0.2%F.S.) |

| Applicable Fuel Cell Types | Pemfc |

| Coolant Temperature Control Range | Rt+5ºC~90ºC |

| Applicable to Reactor Power Range | 10kw-100kw |

| Air Flow Range | 0-8000slpm |

| Hydrogen Flow Range | 0-2000slpm |

| Transport Package | Wooden Case or Container |

| Specification | 6.0*2.2*2.3m |

| Trademark | WOBO |

| Origin | China |

| HS Code | 8419899090 |

| Production Capacity | 1000 Sets/Year |

Product Description

Hydrogen Fuel Cell Test EquipmentLower Running Cost 100Kw Fuel Cells Power Output Analyzer For Reliability Testing

Product Description

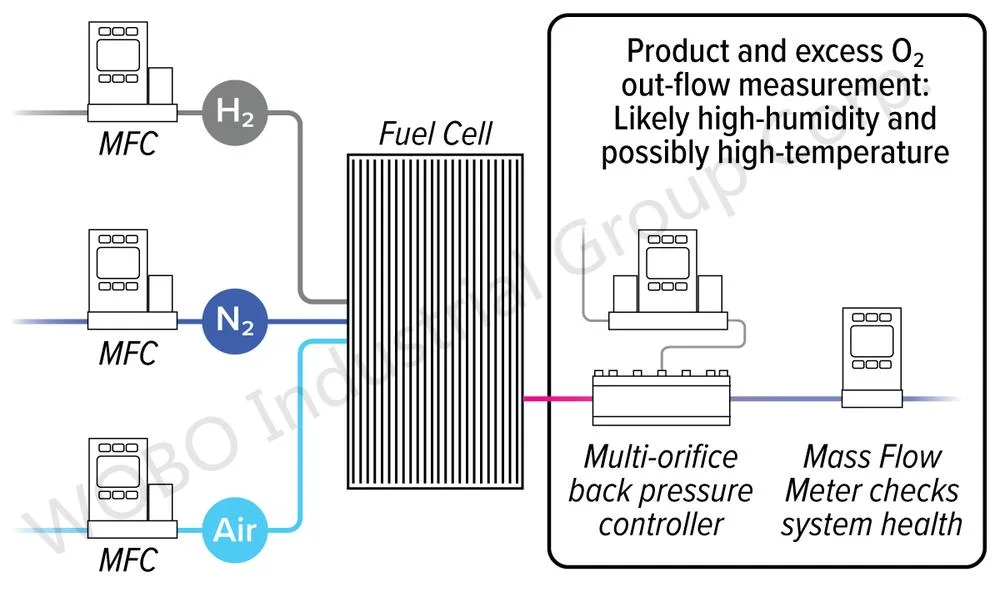

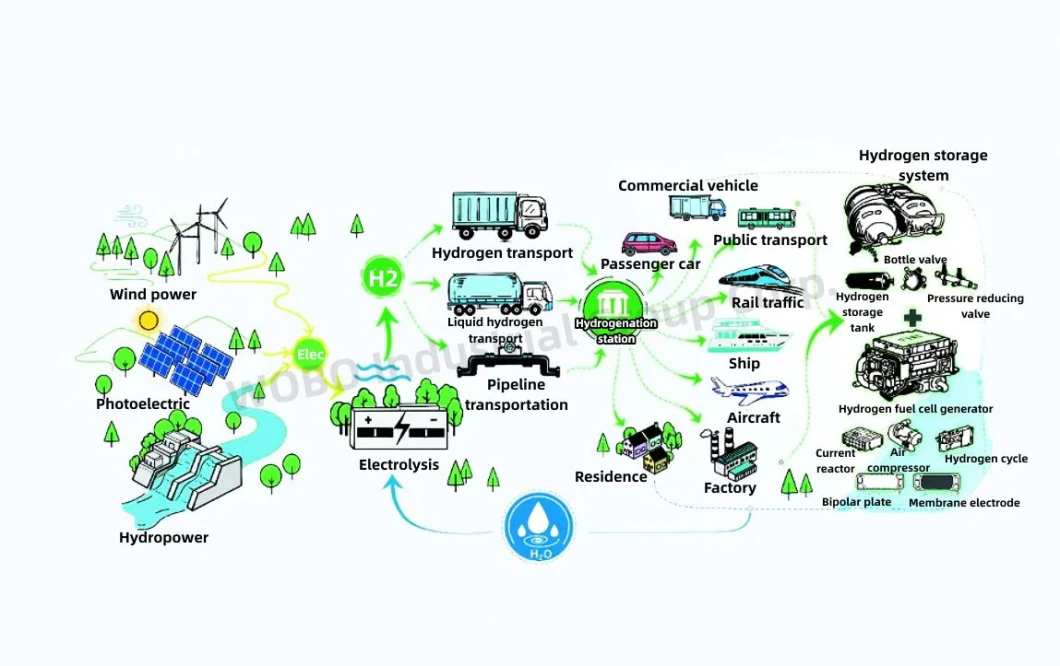

Technical Principle

The technical principle of hydrogen fuel cell test equipment is centered around evaluating and analyzing the performance and characteristics of hydrogen fuel cell systems. It involves several key principles and processes, including: Hydrogen Supply: The test equipment ensures a controlled and continuous supply of hydrogen gas to the fuel cell being tested. It incorporates gas management systems such as gas flow controllers, pressure regulators, and gas analyzers to handle the safe and precise delivery of hydrogen to the fuel cell. Electrical Load Simulation: To assess the performance of the fuel cell under various operating conditions, the test equipment utilizes load banks or electronic loads. These devices simulate electrical loads on the fuel cell, allowing researchers to measure and analyze its response to different power demands. This helps in evaluating the efficiency, power output, and stability of the fuel cell system. Data Acquisition: The test equipment is equipped with sensors, meters, and data loggers to measure critical parameters of the fuel cell system, including voltage, current, power output, temperature, pressure, and gas flow rates. These measurements are collected in real-time, providing researchers with precise data about the performance and behavior of the fuel cell during testing. Control and Monitoring: The test equipment provides control mechanisms to adjust and regulate the operating parameters of the fuel cell system, such as voltage and current levels. This allows researchers to fine-tune the system and evaluate its response to different control settings. Additionally, the equipment enables continuous monitoring of the fuel cell's performance, ensuring that it operates within safe and optimal conditions. Data Analysis and Visualization: The collected data from the fuel cell test equipment is processed and analyzed using dedicated software. This software facilitates data visualization, trend analysis, and the generation of comprehensive reports. Researchers can interpret the data to identify performance patterns, assess the impact of different variables, and make informed decisions regarding system optimization and improvements. The technical principle of hydrogen fuel cell test equipment is to provide researchers, developers, and manufacturers with the tools and capabilities to conduct accurate and reliable testing of fuel cell systems. By measuring and analyzing critical parameters, controlling operating conditions, and facilitating data-driven decision-making, this equipment plays a crucial role in advancing the understanding and development of hydrogen fuel cell technology. Working Principle of Hydrogen Fuel Cell Test Equipment

Applications

| Product name | Hydrogen fuel cell test equipment |

| Applicable to reactor power range | 10KW-100KW |

| Hydrogen flow range | 0-2000SLPM |

| Air flow range | 0-8000SLPM |

| Gas flow control accuracy | ≤±(0.8%RD+0.2%F.S.) |

| Coolant temperature control range | RT+5ºC~90ºC |

| Applicable fuel cell types | PEMFC |

| * Customizing products according to customer requirements. | |

Detailed Photos

Certifications

Send to us