Custom OEM Aluminum Die Casting for LED Lamp Housing Custom Aluminum LED Housing

Overview Package Size 1000.00cm * 1000.00cm * 1000.00cm Package Gross Weight 100.000kg Product Parameters Product Descri

Overview

Detailed Photos

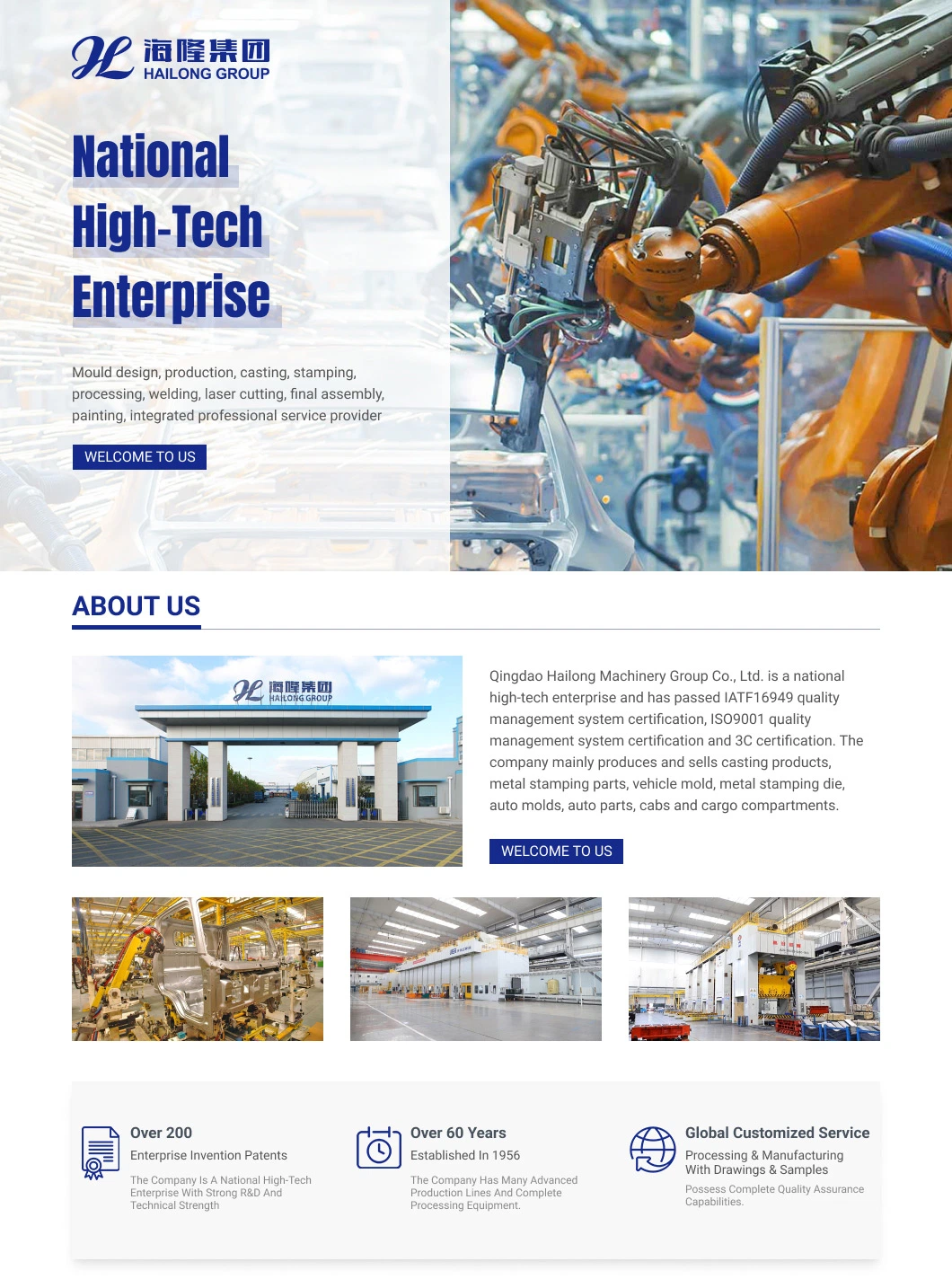

1. TOTAL AREA & MAIN PRODUCTS

1.1 We are a manufacturer established in 2000 year in Jimo District,Qingdao City

1.2. A total area of more than 500,000 square kilometers and the building area of 300,000 square kilometers with 5 factories

included.

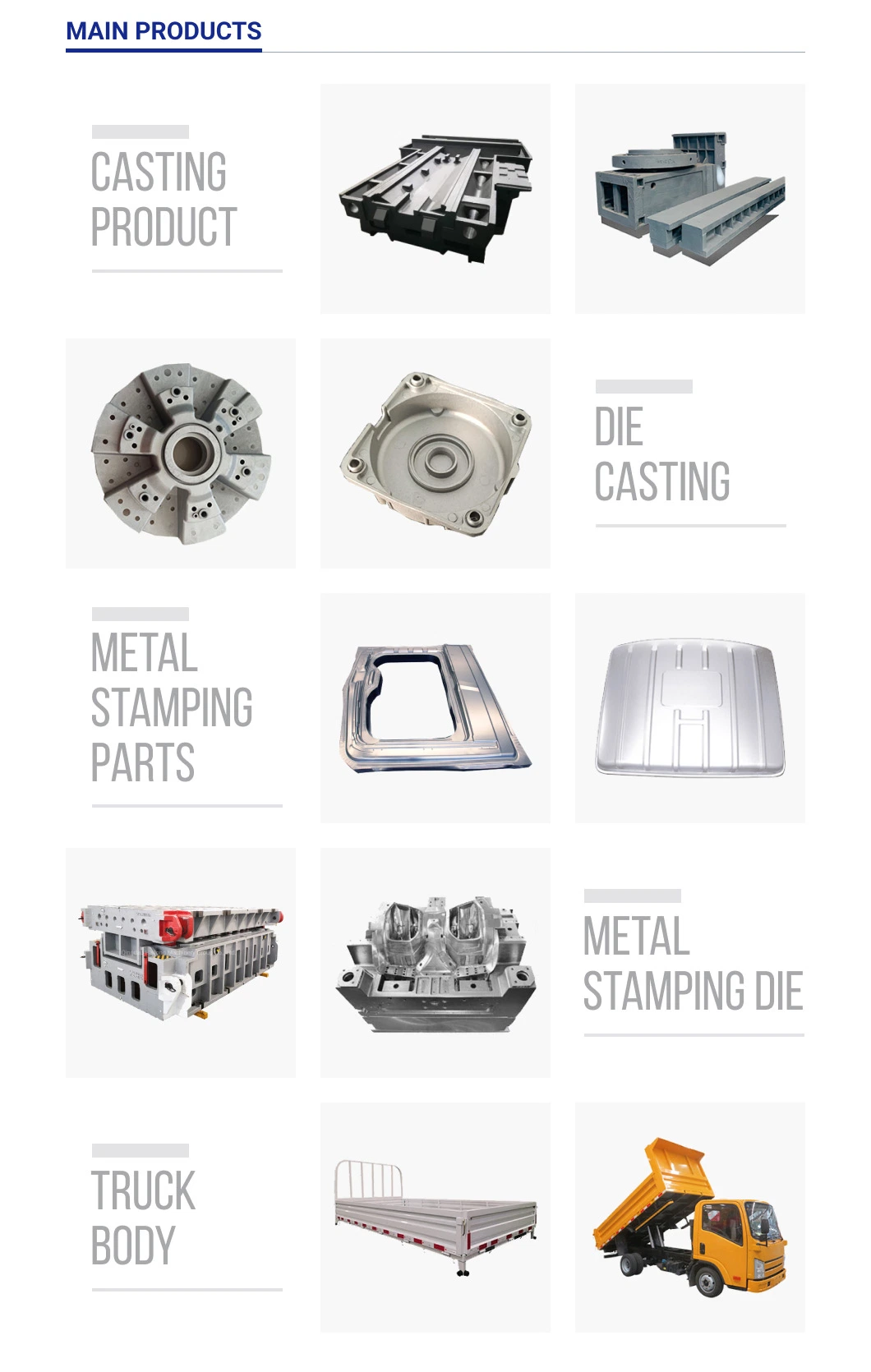

1.3 Our main products are casting products,like vehicle mold,machine tool bed ,gear box,worm-gear case,valve body,compressor

housing, etc, Auto accessories, stamping parts, truck cabin,truck body etc.

2. EQUIPMENTS

Our company has a full chain production capacity of molding, stamping, welding, assembling and coating. The total asset reaches

1.35 billion yuan.

2.1 Large-scale press/stamping equipments with great tonnage span 160T-2400T, also with small punching machine for small stamping

parts.

2.2 ROBOT welding and binding line

2.3 5 center JAPANESE OKUMA CNC machining centers

2.4 Electrophoresis and painting line

2.5 2 tons & 10 tons electric furnace

2.6 Waste collection and dust removal system

3. TECHNOLOGY CENTER

Our technology center was awarded as City-level Technology Center.

3.1 A professional technical team of 40 engineers

3.2 More than 100 domestic patents

3.3 Advanced programming software AUTOCAD,CAM,CAE,CIMATEON,UG etc

3.4 Superior engineering equipments and facilities for detection,like Three coordinate measuring instrument ,Spectral

analysis,Computer carbon and sulfer analyzer,tryout presses etc.4. CUSTOMERSOur products have been exported to America,India, Africa and other countries and regions. and provide OEM service for domesticcustomers,such asFAW Jiefang Automobile,FAW Jiefang Qingdao Automobile,SAIC General Motors Dongyue AutomobileDengfeng Automobile,BAIC Motor and Beijing Benz Automobile,and other well-known automobile factories in china.5. CERTIFICATIONS5.1 ISO9001-2008 International quality management system certification5.2 IATF16949:2009 Quality management system certification5.3 ISO14001:2015 Environmental management system certification5.4 OHSAS18001:2007 Occupational health management system5.5 CCC: China Compulsion Certification(3C)

Basic Info.

| Model NO. | Custom |

| Machining | Machining Center |

| Material | Aluminum Alloy |

| Surface Preparation | Polishing |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 2 |

| Certification | ISO 9001:2008, IATF16949 |

| Additional Process | Deburring,Drilling,Threading,Milling,Turning,CNC M |

| Surafce Finish | as Per Clients′ Requirements |

| Tolerance | 0.01 |

| Transport Package | Crates |

| Specification | Customised |

| Trademark | Hailong |

| Origin | Qingdao, China |

| HS Code | 7616999000 |

| Production Capacity | 1000000pieces Per Year |

Packaging & Delivery

Package Size 1000.00cm * 1000.00cm * 1000.00cm Package Gross Weight 100.000kgProduct Description

Product Parameters| Product Name | Aluminum zinc alloy die castings |

| Process | die casting,sand casting,gravity casting,deburring,drilling,threading,turning,CNC machining. |

| Surface finish | As per the clients' request |

| Needed file to quote | 2D or 3D drawing |

| Quality | 100% test before delivery |

| Certification | ISO9001-2008,ISO/TS16949:2009,ISO14001,OHSAS18001,CCC |

| Service | OEM& ODM |

| Inspection | Three coordinate measuring machine and full laboratory test |

Die castings are widely used in industrial products,like auto parts,housing parts ,lighting,medical parts,furniture parts etc. There are various die castings made of aluminum zinc alloy,copper etc.

Detailed Photos

1. TOTAL AREA & MAIN PRODUCTS

1.1 We are a manufacturer established in 2000 year in Jimo District,Qingdao City

1.2. A total area of more than 500,000 square kilometers and the building area of 300,000 square kilometers with 5 factories

included.

1.3 Our main products are casting products,like vehicle mold,machine tool bed ,gear box,worm-gear case,valve body,compressor

housing, etc, Auto accessories, stamping parts, truck cabin,truck body etc.

2. EQUIPMENTS

Our company has a full chain production capacity of molding, stamping, welding, assembling and coating. The total asset reaches

1.35 billion yuan.

2.1 Large-scale press/stamping equipments with great tonnage span 160T-2400T, also with small punching machine for small stamping

parts.

2.2 ROBOT welding and binding line

2.3 5 center JAPANESE OKUMA CNC machining centers

2.4 Electrophoresis and painting line

2.5 2 tons & 10 tons electric furnace

2.6 Waste collection and dust removal system

3. TECHNOLOGY CENTER

Our technology center was awarded as City-level Technology Center.

3.1 A professional technical team of 40 engineers

3.2 More than 100 domestic patents

3.3 Advanced programming software AUTOCAD,CAM,CAE,CIMATEON,UG etc

3.4 Superior engineering equipments and facilities for detection,like Three coordinate measuring instrument ,Spectral

analysis,Computer carbon and sulfer analyzer,tryout presses etc.4. CUSTOMERSOur products have been exported to America,India, Africa and other countries and regions. and provide OEM service for domesticcustomers,such asFAW Jiefang Automobile,FAW Jiefang Qingdao Automobile,SAIC General Motors Dongyue AutomobileDengfeng Automobile,BAIC Motor and Beijing Benz Automobile,and other well-known automobile factories in china.5. CERTIFICATIONS5.1 ISO9001-2008 International quality management system certification5.2 IATF16949:2009 Quality management system certification5.3 ISO14001:2015 Environmental management system certification5.4 OHSAS18001:2007 Occupational health management system5.5 CCC: China Compulsion Certification(3C)

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. For the die casting products , inside stretching film, outside is plywood case. which is strong enough to ensure the product safety.

Send to us