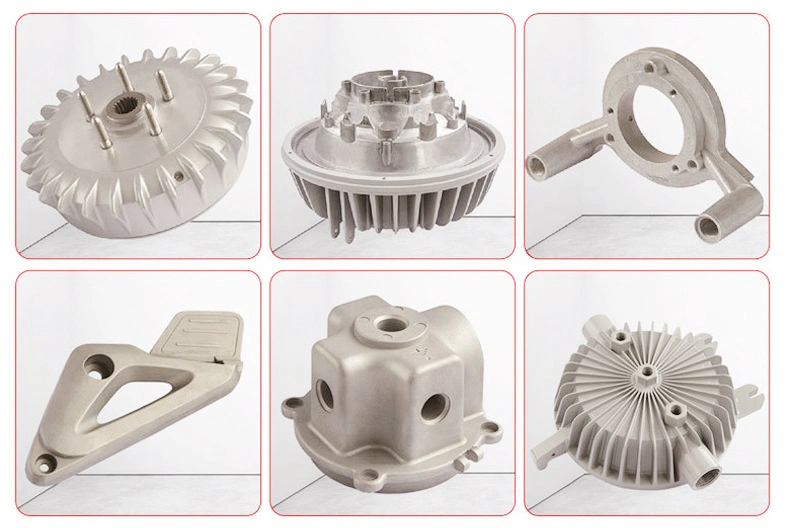

Custom Die Casting Aluminum Alloy Engine Parts with Anodizing

Package Size 30.00cm * 15.00cm * 30.00cm Package Gross Weight 5.000kg Product details Die casting is a manufacturing pro

Basic Info.

| Model NO. | ETND-DC172 |

| Machining | Machining Center |

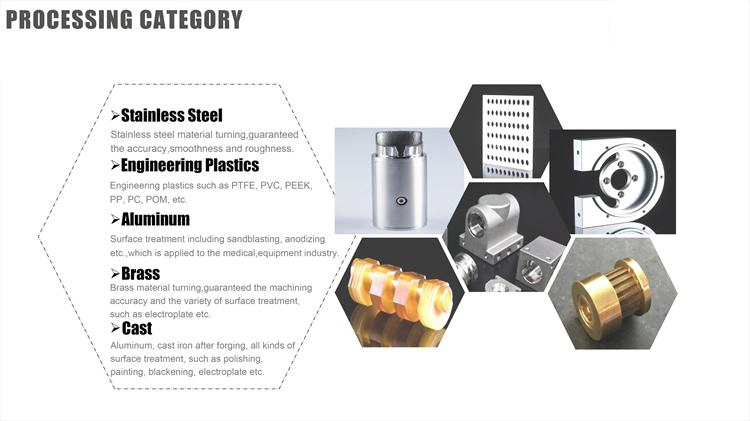

| Material | Aluminum |

| Surface Preparation | Deburring |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 3 |

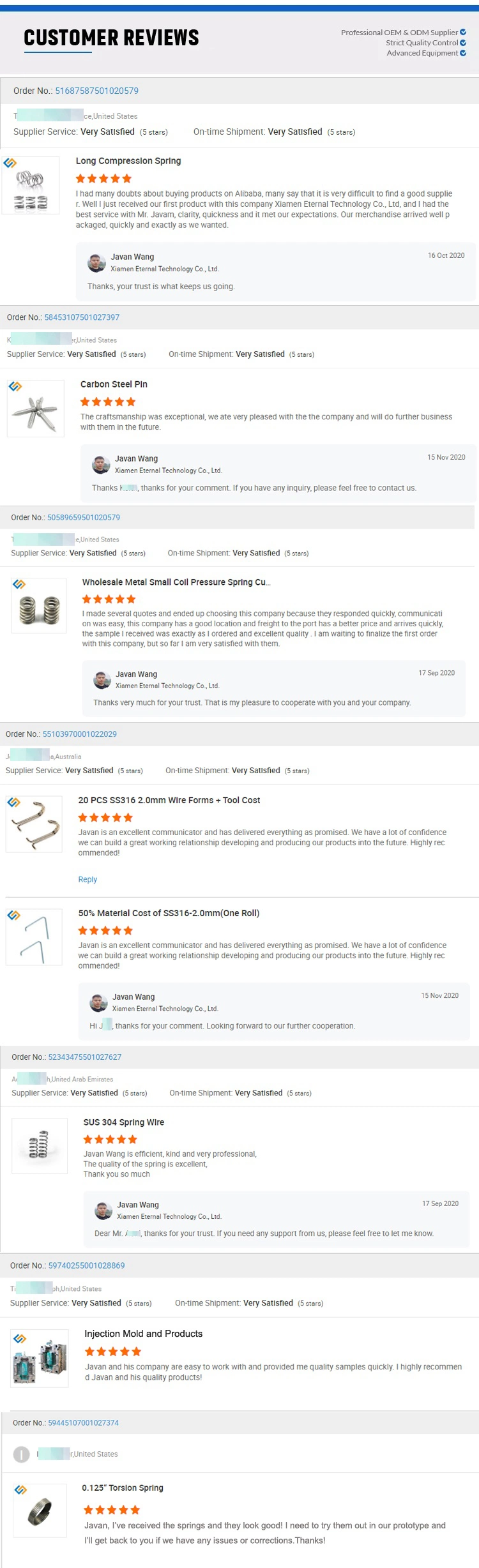

| Certification | ISO 9001:2000 |

| Mould Life | 50000shots |

| QA | Engineer and Inspection |

| Name | OEM Die Casting for Aluminum Electronic Tool Parts |

| Drawing Format | STP/Step/Igs/Dwg/Pdf |

| Transport Package | PE Bag+Carton Box/Customized Packing |

| Specification | CE, SGS |

| Origin | Xiamen, Fujian |

| HS Code | 8503009090 |

| Production Capacity | 300000 Piece/Pieces Per Month |

Packaging & Delivery

Package Size 30.00cm * 15.00cm * 30.00cm Package Gross Weight 5.000kgProduct Description

Product details

| Product Name | Custom Machined Stainless Steel CNC Machining parts |

| Material | ADC10, ADC12, A360, A380, A413, A356, LM20, LM24, Zinc Alloy |

| Cavity | Single or Multiple |

| Surface Treatment | Polish, Powder Coating, Lacquer Coating, E-Coating, Sand Blast, Shot Blast |

| Mold Life Time | 50000 Times |

| Size | Customized |

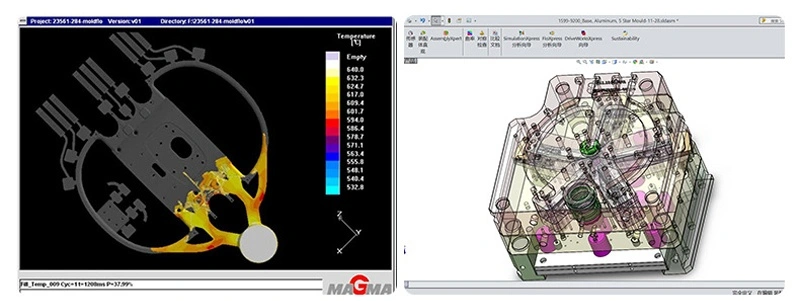

| File Formats | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA, PDF Etc |

| Service Project | Production Design, Technical Service, Mould Design & Processing, Products |

| Quality Assurance | ISO9001:2015 Certified, SGS |

| Application | Industry Appliance, Auto, Energy, Medical Device, Instrumentation Etc |

Die casting is a manufacturing process that involves injecting molten metal, typically aluminum, zinc, or magnesium, into a reusable steel mold known as a die. This mold is designed with intricate cavities and cores that determine the shape and features of the final product. The molten metal solidifies quickly within the die, allowing for high production rates and precise replication of complex geometries.

Accuracy: Die castings have excellent dimensional accuracy and repeatability, ensuring consistent part quality. The ability to create intricate details and tight tolerances makes it ideal for producing complex assemblies.

previous:

Made in China OEM/ODM Die Casting

Send to us